Konecranes’ factories in Sweden and Finland take strides towards reducing the environmental impact of their operations.

Konecranes has taken bold steps to reduce the carbon footprint of its own operations, with its factories in Markaryd, Hyvinkää, and Hämeenlinna leading the way. These three factories have received CarbonNeutral® building certification, highlighting their commitment to reduce global GHG emissions.

Konecranes has taken bold steps to reduce the carbon footprint of its own operations, with its factories in Markaryd, Hyvinkää, and Hämeenlinna leading the way. These three factories have received CarbonNeutral® building certification, highlighting their commitment to reduce global GHG emissions.

On group level, Konecranes already reached its science-based target of halving Scope 1 and 2 emissions – greenhouse gas emissions caused by own operations – in 2022 versus 2019. By the end of 2024, the GHG emissions from the company’s own operations have decreased in total by 56 percent from 2019. These Scope 1 and 2 emissions account for about 1 percent of the company’s total emissions.

The certification has been issued in accordance with The CarbonNeutral Protocol, a global framework for carbon neutrality. Konecranes achieved this certification by minimizing internal emissions through activities such as maximizing renewable energy usage and offsetting unavoidable emissions through the purchase of verified carbon credits, which have an immediate impact by delivering finance to emission reduction projects around the world. Even if Konecranes purchases these carbon credits, the corresponding amount of emissions is not deducted from the total emission calculations that are annually publicly disclosed.

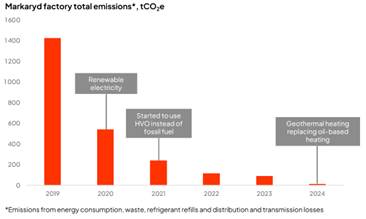

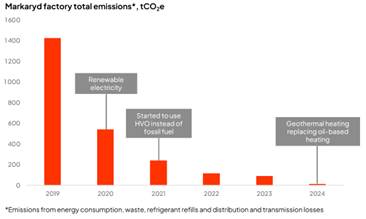

Markaryd factory in Sweden has managed to cut emissions by 99 percent since 2019

The Markaryd factory in Sweden has made impressive progress in reducing its emissions, achieving a remarkable 99% decrease from 2019 to 2024. This achievement is primarily the result of transitioning to non-fossil energy sources and implementing other energy efficiency improvements.

Currently all the energy consumed at the Markaryd factory comes from renewable sources. Geothermal heating has replaced oil-based heating system, and fossil-fuel has been replaced with HVO (hydrotreated vegetable oil). Efforts to reduce energy consumption further extended to the factory's lighting, with the replacement of conventional lighting with LED systems and a reduction in HVO consumption in production processes.

To achieve CarbonNeutral® building certification, Markaryd factory has purchased carbon credits corresponding to the currently remaining 13 tons of CO2e emissions, which are helping to finance the Darkwoods Forest Conservation project in Canada which is working to immediately reduce emissions through nature based solutions.

Konecranes has taken bold steps to reduce the carbon footprint of its own operations, with its factories in Markaryd, Hyvinkää, and Hämeenlinna leading the way. These three factories have received CarbonNeutral® building certification, highlighting their commitment to reduce global GHG emissions.

Konecranes has taken bold steps to reduce the carbon footprint of its own operations, with its factories in Markaryd, Hyvinkää, and Hämeenlinna leading the way. These three factories have received CarbonNeutral® building certification, highlighting their commitment to reduce global GHG emissions.